- surfaces

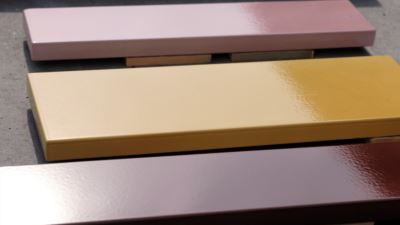

- deep color

The magic of colors

Colors palette designed by David Lopez e Francesco Meda

The intensity and vibration of these innovative glazes accentuate shades attainable only by lava.

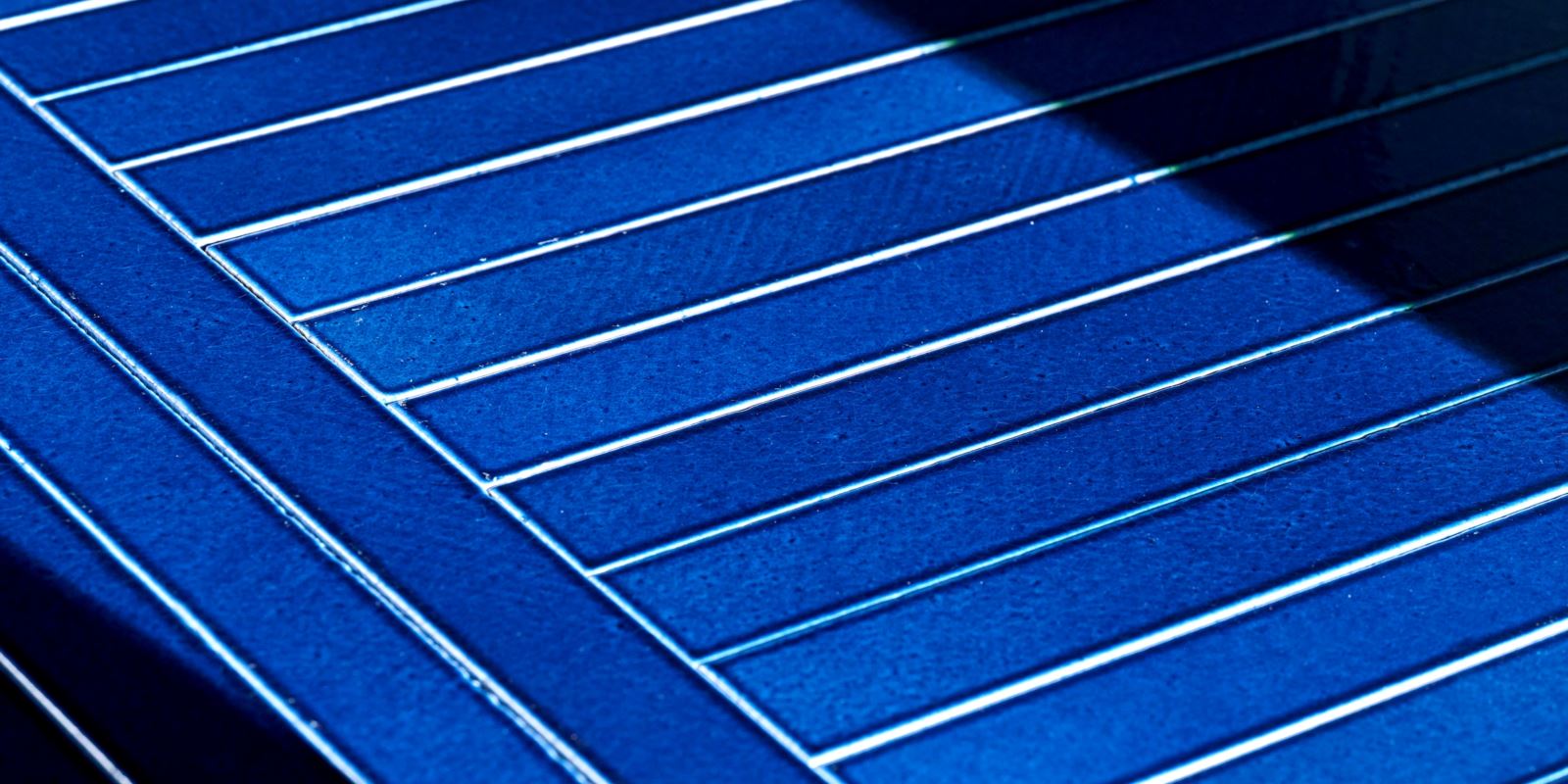

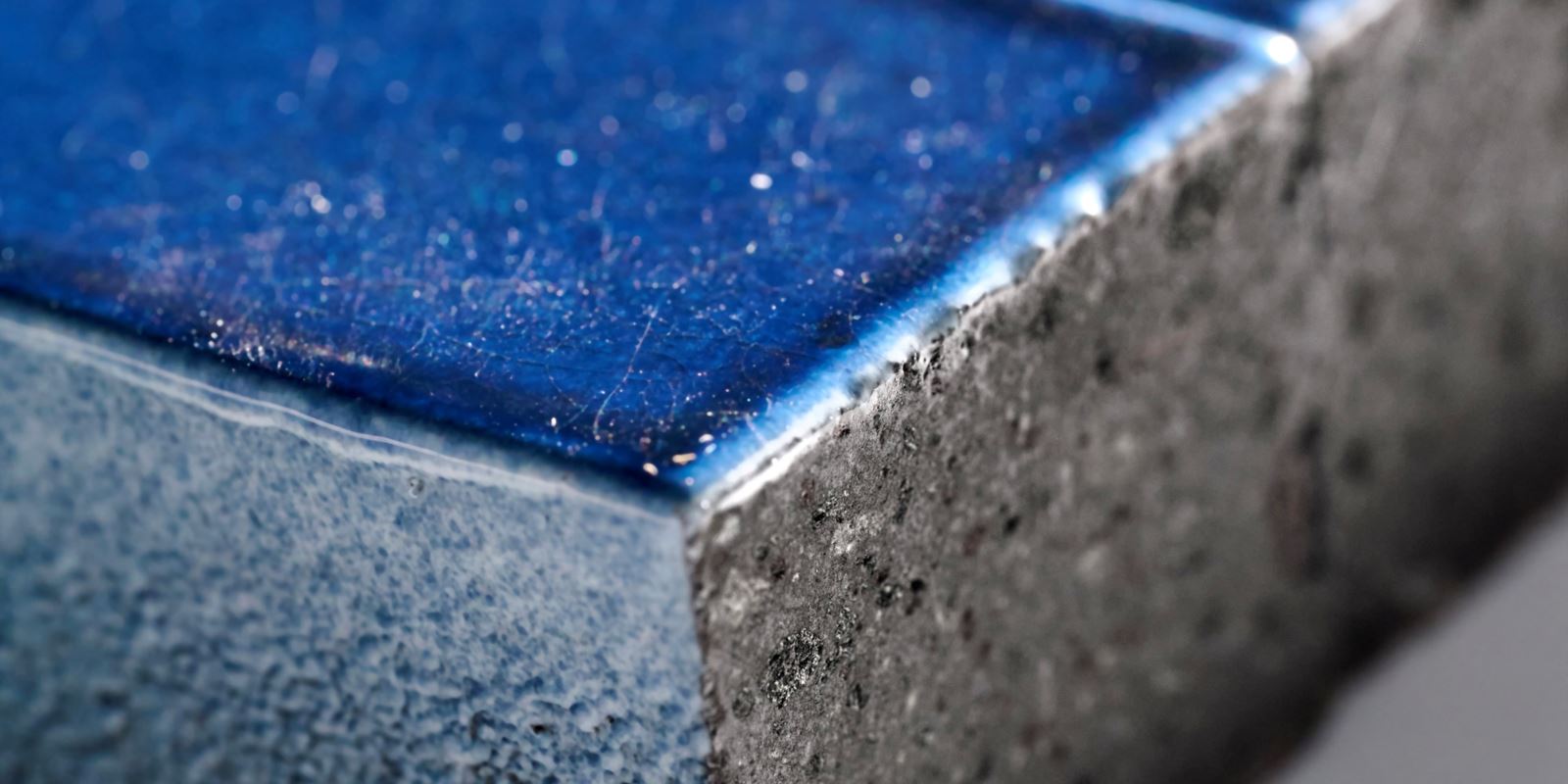

Why glazing

The glazing of lava stone requires scrupulous workmanship and every stage is done by hand.

Many factors are taken into account, including the features of the lava stone piece, which, since it is natural, are not always uniform.

After being cleaned, completely dried and covered with a clay paste called engobe, which serves to close any microscopic holes or imperfections in the stone, we come to the main stage, i.e. applying the previously prepared and mixed liquid clay glaze.

This step is repeated several times, bringing into play the skill of the craftsman.

Once glazed, the lava stone piece is left to dry naturally.

The last stage before firing is the application of a vitreous glaze over the colored surface.

The transparent glaze is prepared by mixing several raw materials as well as various minerals and oxides to obtain the desired color, level of gloss and finish.

We work with a natural stone and the process is strongly handmade, this process is completed in the ovens at 1000 degrees Centigrade; These temperatures and humidities also have an influence, as do the project stone sizes, slab thicknesses and finishes. The pictures on our website and catalogues as well as the commercial samples we supply may have slight variations, for this reason we recommend that you order a control sample at final order confirmation which focuses all parties on the project success.